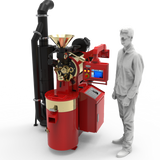

Toper 3kg Gas or Electrically Heated Coffee Roaster

|

Model: |

TKMSX3 Gas |

||

|

Batch Capacity: |

3 kgs of green coffee. |

||

|

Roasting Time : |

Brown roast: 12 Minutes Dark roast: 18 Minutes. |

||

|

Cooling Time |

4 Minutes ( for room temperature ) |

||

|

Hour Capacity : |

Brown Roast – 8 kg / Hour Dark Roast – 6 kg / Hour |

||

|

Daily Capacity : ( For 8 Hours ) |

Brown Roast – 64 kg / Daily Dark Roast – 48 kg / Daily |

||

|

Dimensions (W*H*D) |

135 x 192 x 125 Cm |

||

|

Weight : |

375 kgs |

||

|

Voltage : |

110-220-380 Volts, 50-60Hz, 1-3 Phase are available regarding to customer preference. |

||

|

Heating System |

LPG / Natural Gas. 1/2 inch fitting |

||

|

Consumption |

1,5 KW / Hour |

||

|

Type of Roasting : |

Thermal Transfer Roasting |

||

|

Number of Motors |

4 motors |

||

|

Color : |

Black |

Red |

|

|

Green |

Other |

||

|

Body Type : |

Stainless steel body , Brass body |

||

Outlet ducting is required, 150mm Diameter. Required Air Volume (m3/h) 350

Temperature Control: Digital Temperature controls and Digital Temperature indication Other Specifications:

- Standard timer, Security drawer for the beans

- New type chaff collector for easy chaff discharging

- Simultaneous roasting and cooling at same time

- Sampler and glass window to control roasting and viewing window for green bean hopper.

- Installation and start up manual for easy using

- High capacity suction for cooling fan

- 1 year guarantee

- Gas and electric components are compatible to CE – UL standards

- Testing Lamp (for checking roasting results at the same color in the same lighting conditions).

- A detailed user manual is provided with each machine

- Drum adjustment tool also provided with the machine

- Rake wheel for cleaning cooling tray.

Security Systems :

Gas Security & pilot system for security and electronic ignition : Cut the gas connection

Mixer security system: To protect any injury to user from rotating cooling tray arms.

MAIN PARTS OF TKMSX 3 GAS COFFEE ROASTER

2- GREEN COFFEE HOPPER VALVE: By opening this valve, the green beans fall inside the drum.

3- SAMPLER SPOON : Enables to check the beans during the roasting.

4- DUST ROOM GATE: to open and clean inside the dust room. There is two gates on the dust room. Above gate is not usable during the roasting. Do not open it during roasting. You can use the below gate for cleaning the dust room during roasting

5- COOLING TRAY: Cools the coffee beans in three minutes.

6- MIXER DISCHARGE GATE: You can get the coffee beans out from this gate.

7- VIEWING WINDOW: Enable to see roasting process inside the drum during the roasting.

8- BURNER ROOM: Pilot flame and burner is inside this area as well as the flame

9- DUST DRAWER: For cleaning the chaffs which drop down during the roasting from the drum gap.

11- ELECTRICAL CONTROLBOX: All electric circuits is included inside this box.

12- DUST ROOM (CHAFF COLLECTOR) : Collects the chaff from exhaust air and not let the chaff go out of the exhaust system.

13- LAMP: Enable to follow the roasted beans at the same light conditions in every roasting.

14- EXHAUST PIPE: You connect chimney this point.

Price is for crated delivery of the roaster to your commercial premises only. All connection to gas, electricity and ducting to be arranged by yourselves using appropriately certified engineers using the manufacturers specifications. Warranty is twelve months parts and labour Warranty, in the event of a fault we will obtain a replacement part and send it to you and then arrange for someone to fit it. If you are going to require rapid repairs you are strongly advised to make use of local engineers, the majority of commercial espresso machine engineers will be able to work on these machines - and the most likely failure is the drum or fan motors which are easy to replace and readily available from UK motor specialists.

The Gas Roaster requires 150mm Aluminium Ducting venting outside, this ducting is also the flue for the gas burner. When you have the gas burner commissioned by a gas safe engineer, ensure they check your ducting is suitable as a flue for the burner. Gas burners consume oxygen, so you should always be roasting in a well ventilated room. As with any gas burning appliance a carbon monoxide detector is strongly advised.

PLEASE NOTE, THE ELECTRICALLY HEATED VERSION OF THIS ROASTER DOES NOT HAVE AN EXHAUST TEMPERATURE PROBE - IT USES TWO PROBES IN THE DRUM, ONE TO MEASURE BEAN TEMPERATURE AND ONE TO MEASURE THE HEATING ELEMENT TEMPERATURE.

Ducting Requirements

All makes of coffee roasters and oxidizers have a blower mounted inside which forces exhaust air into the ducting. The oils and residues in the exhaust air are flammable. In the event of a ducting/flue fire, the internal duct temperatures can exceed 1000° F (538°C), which could cause nearby combustible materials to ignite. For this reason, it is advised to use at least stainless steel double wall positive pressure grease ducting (UL certified for USA or CE for European Union).

ROASTER: Ducting must be suitable for 1000°F (538°C) continuous and 1400°F (760°C) intermittent operating temperatures.

Note: Under no circumstances should Class B or Spiral-wrap ducting be purchased.

The exhaust system must be designed to operate with a static flue pressure between positive 0.25”WC and negative 0.15”WC at the exhaust of the roaster while in operation.

Designing an exhaust system requires a trained professional to calculate the efficiency of the system and proper size of duct. The ducting must be of sufficient diameter to accommodate the ACFM (actual cubic feet per minute) or ACMH (actual cubic meters per hour) of airflow. A knowledgeable Heating, Ventilation, Air Conditioning (HVAC) contractor can assist you with the best ducting layout for your site.

It is the responsibility of the roaster purchaser to ensure they fit adequate ducting that complies with regional regulations, we can supply details of experienced roaster consultants who can provide guidance on the entire roaster location, fitting and ducting as well as additional back up support. The rates vary depending on requirements and you would need to contact them first to confirm costs and to arrange to pay them seperately for this service.

Unless otherwise specified, Toper Roasters are built to order by the Factory in Turkey. Normal turnaround from a confirmed order is 6 to 8 weeks, although Toper do sometimes have stock available or being built for stock so it is always worth contacting us to confirm a delivery time on any specific model. Prices include crated delivery to your premises only, removing the roaster from the crate and into your premises will be at your own cost. Fitting suitable extraction, connecting to electricity and gas supplies as required will also be at your cost. Warranty covers non-wearing parts only, should an issue arise a replacement part will be sent to you and then an engineer arranged to fit the part. Warranty does not include issues caused by failure to clean the roaster, especially where chaff is allowed to build up or where the fan is not cleaned as per the roaster manual specification. All the general maintenance instructions in the Toper user manual should be followed in full, issues caused by failure to perform tasks such as drum alignment as per the manufacturers instructions will be full chargeable to resolve.

This equipment meets the following standards:

CSA ANSI Z83.11-2006/CSA 1.8-2006 Gas Food Service Equipment, MD 2006/42/EC, LVD 2006/95/EC, EN 291-1:1991, EN 292-2:1995, EN 294:1992, EN 6020-1:1997, EN 1050:1996